PRODUCTS

2003

Our Products Range

Explore our complete range of high-quality products designed for consistent printing accuracy and reliable production efficiency.

High-Precision Printing Doctor Blades

Our premium-grade Doctor Blades are engineered for high-performance ink metering. Manufactured from superior-quality steel, they ensure a consistent wipe across the cylinder, reducing wear and preventing streaks.

Key Features:

High wear resistance

Smooth edges for cylinder protection

Consistent pressure distribution

Ideal For:

Rotogravure and Flexographic printing presses

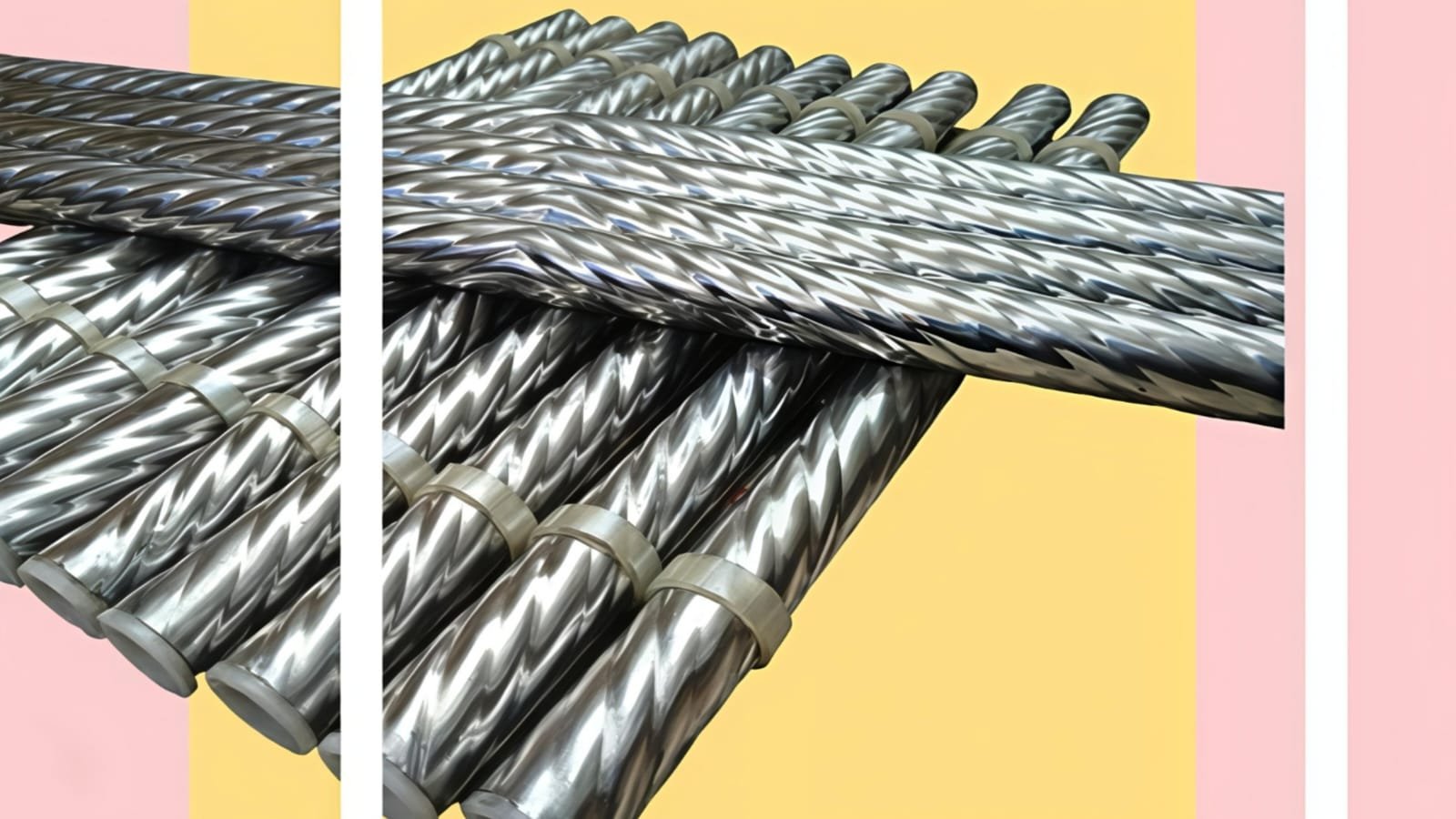

Specialized Ink Mixing Rollers

Maintain perfect ink consistency with our heavy-duty mixing rollers. These prevent ink skinning and ensure a uniform temperature throughout the fountain.

Available Variants:

With Rope (Nylon Braided): Designed for enhanced surface agitation and deeper mixing

Without Rope (Smooth): Ideal for standard mixing requirements and easy cleaning

Benefit:

Reduces waste and ensures color accuracy during long runs

Precision Wire Bar Coater (Meyer Rods)

Achieve precise and uniform coating thickness with our high-accuracy Wire Bar Coaters. These are essential for applying consistent films of ink, lacquer, or adhesives on various substrates.

Key Features:

Stainless steel construction

Available in various wire diameters for specific coating weights

Ideal For:

R&D labs, quality control, and thin-film application

Maple Corona Dye Test Pens

The industry standard for measuring surface energy. These pens provide an instant and accurate "Dyne Level" reading to check if your material is ready for printing, laminating, or coating.

Function:

Quickly identifies if the Corona Treatment on plastic films is sufficient

Accuracy:

Reliable results for PP, PE, PET, and other non-absorbent materials

High-Temperature Teflon (PTFE) Dams

Our PTFE (Teflon) Dams are designed for superior chemical resistance and high-temperature stability. They act as perfect barriers in the ink fountain to prevent leakage and manage ink flow.

Key Features:

Non-stick surface

Highly durable against aggressive solvents

Benefit:

Minimizes maintenance and prevents cross-contamination of inks

Standard Viscosity Cups (Zahn/Ford/B4)

Ensure the perfect flow behavior of your inks and coatings. Our Viscosity Cups are calibrated to provide accurate measurement of liquid thickness to maintain print quality.

Usage:

Simple “dip-and-time” method to ensure ink is within the required specifications

Material:

Corrosion-resistant stainless steel/aluminum for long-term durability

FREQUENTLY ASKED QUESTIONS

Find quick answers to common questions about our products, ordering process, shipping, technical support, and policies to help you decide confidently.

Ans: Our Doctor Blades are manufactured using high-quality refined steel and specialized alloys to ensure high wear resistance and a clean wipe every time.

Ans: Yes, we offer Wire Bar Coaters in various micron sizes and lengths to match your specific coating thickness requirements.

Ans: Rollers with rope provide better surface agitation for thicker inks, while non-rope (smooth) rollers are easier to clean and ideal for standard viscosity inks.

Ans: Always keep the caps tightly closed when not in use and store them in a cool, dark place to prevent the ink from evaporating or degrading.

Ans: Yes, our PTFE dams are chemically inert, meaning they are resistant to solvent-based, water-based, and UV inks.

Ans: Yes, we understand the importance of precision. You can contact our sales team to request samples for quality evaluation.

Ans: For in-stock items, we ship within 24–48 hours. Bulk or custom orders typically take 5–7 business days depending on the specifications.

Ans: Absolutely! We offer competitive tiered pricing for large-scale industrial orders. Please reach out to us for a custom quote.

Ans: If the product has a manufacturing defect or is damaged during transit, we offer a hassle-free replacement. Please report any issues within 7 days of delivery.